Koidra co-founder Ken Tran speaks about the power of AI in horticulture in this article in Greenhouse Grower.

In 2018, five teams grew cucumbers in a ground-breaking Autonomous Greenhouse Challenge international competition. The twist: only one of the teams consisted of experienced human growers operating their greenhouse compartment manually. The remaining four teams consisted of international experts in the fields of horticulture and artificial intelligence (AI). They worked to develop AI solutions to manage their crops remotely and autonomously. The goal of the competition, the world’s first Autonomous Greenhouse Challenge, was to drive breakthroughs in sustainable food production.

After four intense months, the manual growers came in second place. The first-place team, led by one of the authors of this article, won with an autonomous growing solution that not only achieved 6% greater yields and 17% higher net profit, but also used less CO2, heating, and water inputs.

Unfortunately, growers know all too well that labor is the biggest source of problems in production. Year after year, in Greenhouse Grower’s Top 100 Growers survey, growers report challenges not only with the cost of labor but also with the availability of skilled labor. Not surprisingly, growers are increasingly looking for ways to address these challenges, including new technologies that can make greenhouse management more autonomous.

AI Is a Step Beyond Rules-Based Automation

A good way to think about artificial intelligence is that it is a step beyond simple rules-based automation. Modern AI is all about the use of mathematics to find patterns in data, including the kind found in greenhouse environmental and biological systems. For example:

- With enough climate data, growers can use AI to determine optimal setpoints and make climate predictions.

- With enough crop yield data, growers can use AI to generate yield forecasts.

- With enough image data, growers can use AI to detect pests and diseases.

Some types of AI can even learn from new data, delivering incrementally better results over time.

By being able to provide deeper insights in day-to-day greenhouse operations, AI can be used to support expert decision-making and empower growers in a meaningful way. After all, the best results come from a thoughtful combination of human intelligence and artificial intelligence.

The data-based approach of AI can also be combined with the classic rules-based approach, allowing for a much higher degree of greenhouse automation than ever before. In short, growers can use AI to automate many rote operational tasks, helping to relieve the chronic labor issues that challenge the industry.

Data Is the Fuel for AI

As much as AI is about mathematical algorithms, it’s also about data. Contrary to popular belief, some of the most common algorithms used in AI have been around for decades. They are not even terribly complicated. But for the longest time, the availability of data — along with affordable computational power required to process the data — have been limiting factors.

It took a recent development in computer hardware to unlock the potential of AI. The smartphone revolution, sparked by Apple in 2007, created entirely new manufacturing ecosystems and supply chains on a global scale. This changed the fundamental economics of computer hardware, seemingly overnight. Key hardware components, such as microprocessors, radios, and sensors, became exponentially cheaper, smaller, and more powerful. The trickles of raw data turned into floods. The new abundance of data and computational power helped to transform AI from a research curiosity with few commercial applications into a technological sea change.

Photo provided and copywrighted by Koidra Inc.

IoT Brings an Abundance of Data

In the early 1980s, graduate students at Carnegie Mellon University in Pittsburgh became annoyed at trekking over to a Coca-Cola vending machine only to find it empty. They modified it so it could report its inventory over the Internet. In doing so, they invented the world’s first Internet-connected appliance.

Today, billions of devices, large and small, from consumer electronics to industrial machines, have joined that first soda machine in being connected to the Internet, forming what’s known as the Internet of Things (IoT). What’s significant is that, unlike earlier generations of hardware — including many common greenhouse automation solutions — IoT devices use the same kinds of data formats and communication protocols as used elsewhere on the Internet. By relying on global Internet standards, it can be easier to exchange data with IoT devices without requiring extra hardware to bridge from one type of system to another.

Together, AI and IoT are complementary technologies. IoT hardware helps growers collect raw data from greenhouses more easily. And AI software helps growers make sense of — and act upon — that data to improve crop production.

Case study: Kenneth Tran’s Success in the Autonomous Greenhouse Challenge

Dr. Tran: In 2018, I was an AI researcher at Microsoft Research near Seattle, working on a newer type of AI known as reinforcement learning. There I initiated a new effort to apply our research to the domain of controlled environment agriculture. With the so-called Sonoma project, we collaborated with plant scientists at the Harrow Research Center in Ontario, Canada, and ended up competing in the first international Autonomous Greenhouse Challenge, organized by Wageningen University & Research in the Netherlands.

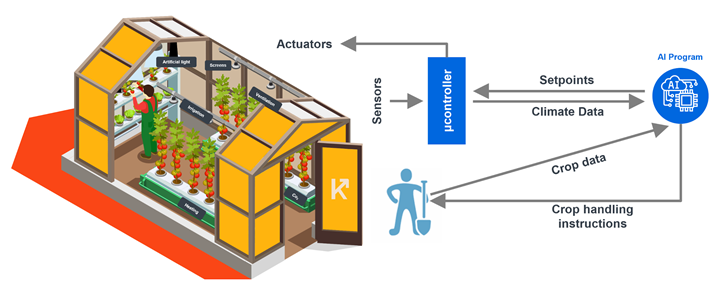

In this challenge, each team grew cucumbers in a 315 square-foot greenhouse compartment for a duration of about four months. These compartments were equipped with standard process computers, climate sensors, and actuators. Using IoT digital interfaces (REST APIs), our AI programs could continuously read data from the sensors, determine optimal setpoints, and send setpoints back to the process computers — all over the Internet. More details about the challenge and its results can be found in an article by Hemming et al. (2019).

Despite our lack of experience in growing cucumbers and our very early-stage prototype, our autonomous growing solution was able to win the competition. We even outperformed the second-place team, the reference team composed of expert Dutch growers, with a 6% higher yield. That margin in yield was equivalent to a 17% increase in operating profit.

Did the reference team perform poorly? Not at all. They performed remarkably well, according to many experts. Their yield was almost 50 kg/m2 in the span of four months, which is the equivalent of almost 150 kg/m2 per year. This is considered high yield for a greenhouse anywhere on the planet.

As a result of the Autonomous Greenhouse Challenge, I founded Koidra in 2020 to directly build upon our learnings and further push the state-of-the-art in AI and IoT for agriculture and other industrial control applications.

Asking the Right Questions About AI and IoT

Today, more greenhouse growers are willing and ready to adopt AI and IoT. The main challenge is making sense of the products on the market and being able to wade through all the marketing speak. A lot of companies eagerly claim that they have an AI algorithm or IoT device that will work for greenhouses.

Here are some key considerations to keep in mind when evaluating AI software and IoT hardware:

- Performance: Growers should be able to see concrete, real-world benefits. Ask: Has the AI been proven in commercial production to improve yield and resource efficiency? Under what conditions? What is the track record of the company in developing AI and IoT software?

- AI design: The most effective AI solutions combine the best of human intelligence with the best of artificial intelligence to make decisions. Ask: How does the AI model leverage the existing body of knowledge? How does it ensure that performance will improve over time with more data?

- Software design: Growers should remain in control of greenhouse operations. Ask: What software design principles are used to ensure crop safety? Can I switch easily between manual, recommendation, and copilot modes at all times?

- Data ownership: Growers should own their data and avoid “vendor lock-in.” Ask: Can I easily import data from other systems? Can I back up and export my own data? Are there APIs which allow for live data access and custom integrations? Can I use software and hardware from different vendors, now and in the future?

AI and IoT Can Empower Growers

In a world in which critical resources — water and energy, as well as time, money, and skilled labor — are becoming more scarce, it makes sense to explore new technologies to alleviate that burden. As we learned from the Autonomous Greenhouse Challenge, growers indeed can achieve greater yields and higher resource usage efficiencies with the use of AI software and IoT hardware. What’s more, these technologies continue to be developed and advanced at a rapid pace.

Ultimately, AI and IoT can truly empower greenhouse growers — to make better decisions, to do more with less — to grow the world’s food more sustainably.

About Koidra

Koidra is at the forefront of climate tech innovation, offering intelligent automation solutions that enable high-tech greenhouses, biomass energy facilities, and food processing plants to excel in both sustainability and production efficiency. We are dedicated to helping these industries reduce their environmental impact while maximizing operational effectiveness.

By integrating advanced machine learning, IoT technologies, and principles from Math and Physics, our systems extend the precision and efficiency of operations beyond what’s possible through human efforts alone. Koidra’s smart automation empowers facilities to broaden their control, minimize reliance on manual expertise, and embrace a scalable approach to environmental responsibility in industrial automation.